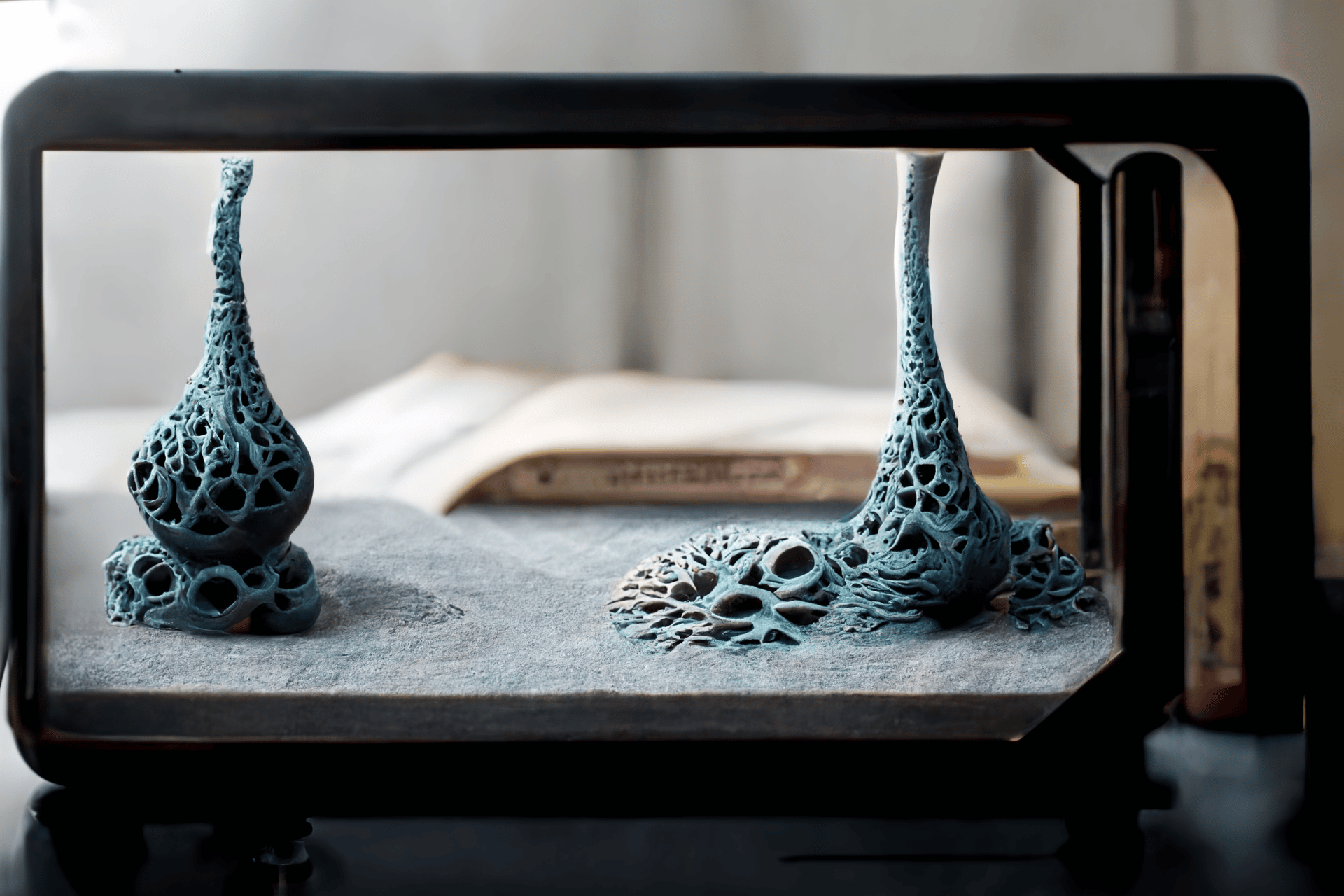

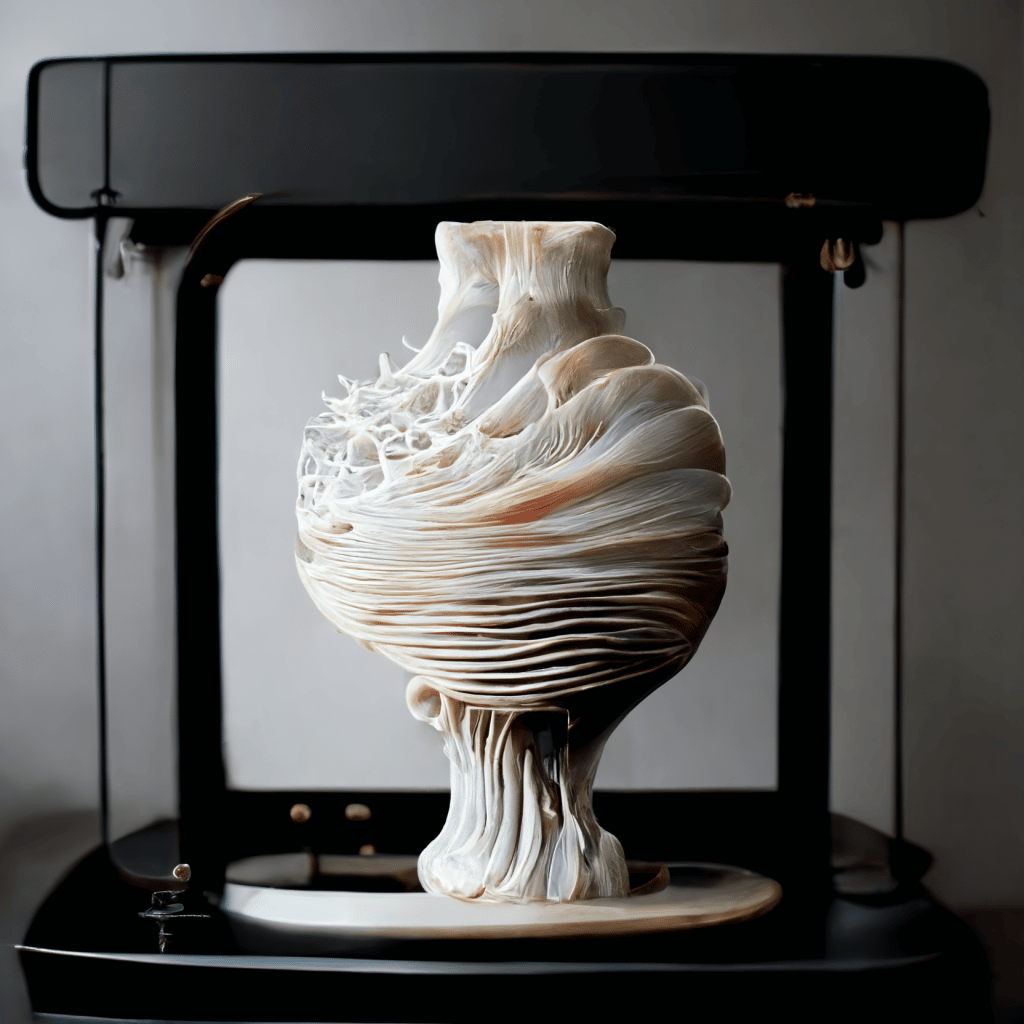

3D Printing is a new technology revolutionizing how we manufacture products. It is a process of making three-dimensional solid objects from a digital file by depositing material layer by layer.

3D printers are now widely used in many different sectors, from engineering and design to healthcare, education, construction, and art. In addition, the market for 3D printing jobs has increased in recent years as the technology becomes more affordable and accessible to consumers.

This article will explore the different 3D printing jobs available today and how you can start your career in this exciting field!

What is 3D Printing?

3D printing is the technical process of making three-dimensional solid objects, starting with a digital file. 3D printing uses additive processes, meaning an object is created by laying down successive layers of material until successful object creation.

3D printing is additive, the polar opposite of subtractive manufacturing. That method is cutting out / hollowing out a piece of metal or plastic with, for instance, a milling machine. Instead, 3D printing enables you to produce complex shapes using less material than traditional manufacturing methods.

The remarkable thing about this form of manufacturing is that the applications are nearly limitless. For example, with the development of Advanced Materials, even printing human body parts have become possible.

For people considering changing careers and looking for cutting-edge challenges, switching to 3D is an option.

3D Printing Jobs – The Good, The Bad, and the Ugly

As demonstrated by this Indeed listing for 3D Printing Jobs, more are becoming available daily. Careers like Additive Manufacturing Technicians and Innovation managers are commonplace.

It may be the correct time to consider career paths in emerging technology. 3D Printing represents a path that will improve for decades. However, in many industries, the use of 3D tech remains in the nascent stages.

The most established part of the industry, Hardware, Software, and Services, is already a nearly $14 billion sector in the U.S.

Areas include selling and servicing printers, software to design 3D models, and value-added resellers targeting specific niches with solutions. Depending on your current skill set, you should look for places that relate closely to your present experience.

Engineering jobs are demanding, and every career path requires a solid technical foundation. However, since the long-term growth prospects look good, it could be worth the effort for some workers to migrate out of dying industries to greener pastures.

How Do I Get a Job in 3D Printing?

How closely does your CV match with in-demand 3D Printing jobs? First, you must meet technical requirements to land a gig like all advancing industries.

Consider the precise types of jobs available in 3D. Here’s leading 3D artist Grant Abbit giving a rundown.

How Do I Start Free?

So, you don’t have two nickels to rub together, but you want to be the next big thing in 3D? Good for you, and fortunately, there’s a way.

Head to Blender.org and download the newest version of the 3D design software.

Blender is a remarkable open-source project with significant corporate and community support.

You can learn the program by watching Youtube Videos and practicing at no cost. Then, when your skills are sufficient, you can make models to sell in 3D marketplaces for the gaming, cinematic, and printing markets.

Experts say that 21.5 million printers per year will be moving by 2030. That’s a massive increase in devices that need 3D Models. Learning how to design them could become a career for self-learners, even with no budget for education.

Entrepreneurs are starting new on-demand 3D printing services – Fabshops are small businesses that offer 3D printing services to their customers. Entrepreneurs can start with a background in 3D printing and become familiar with the software and hardware needed to run a fabshop. Fabshops can be created as standalone businesses or as part of a larger company.

The first step in starting a fabshop is to create a business plan. The business plan needs a marketing strategy and a detailed budget.

Once the detailed business plan is complete, the next step is to find a location for the fabshop. The ideal location is an area with a high concentration of businesses that could use 3D printing services. It is also essential to have access to quality 3D printers and other equipment necessary for running the business.

After securing a location, the next step is to hire employees. The fabshop should have a team of skilled professionals who can design and print 3D parts and components.

The final step is to market the fabshop to potential customers. You can do this through online advertising, word-of-mouth marketing, tradeshows, and conventions.

The Future of Jobs and 3D Printing – Is the Technology Disruptive?

3D printing will likely disrupt nearly every industry. Manufacturing becomes more localized thanks to 3D printers and as the pace of deglobalization continues, expect a massive upswing.

Local car repair facilities are a prime example of beneficiaries of this tech. Once, they would have to search through catalogs to find an in-stock part and wait for it to ship. Now, they can get one locally, thanks to on-demand printing. That cuts down on carbon emissions and costs and is a better end-user experience.

As printers become faster and more powerful, the deployment of applications intensifies. Even with massive growth numbers, we’re at the beginning of a gigantic revolution thanks to the incredible 3D printing tech.

Affordable Housing Is Within Reach

3D printing is a technology quickly disrupting many industries with its ability to produce objects at a fraction of the typical effort, cost, and time it would take using traditional methods. The housing industry is no exception, with 3D printers capable of printing the foundation and walls for a small home in less than 24 hours at a fraction of the cost of traditional construction.

This technology can revolutionize the housing industry by making home ownership more affordable and accessible to all. It could also help reduce homelessness by providing an affordable, sustainable alternative to traditional construction. Some impressive feats of 3D-printed homes have already been achieved worldwide, including a house printed in just 24 hours using a mobile printer and a 3D-printed home on Mars!

The benefits of 3D-printed homes are clear, and it is only a matter of time before this technology becomes mainstream and changes how we think about housing.